ADSS Fiber Optic Cable ( All Dilecric Self Supporting )

Oriental Fiber is delicate to manufacturing high quality ADSS fiber cables to distributors and fiber internet providers to reduce cost and grow business with Worry Free Solutions.

- Top Rated ADSS Fiber Cable Manufacturer

- 6 to 576 cores ADSS Cable for options

- Single Jacket or Double Jackets for long distance Span

- Trusted by big brands and Fiber Internet Service Providers

- Free Sample Available for Testing

- Short Lead Time for Bulk Order

- 13 Fiber Cable Experts for your Customization

Introduction

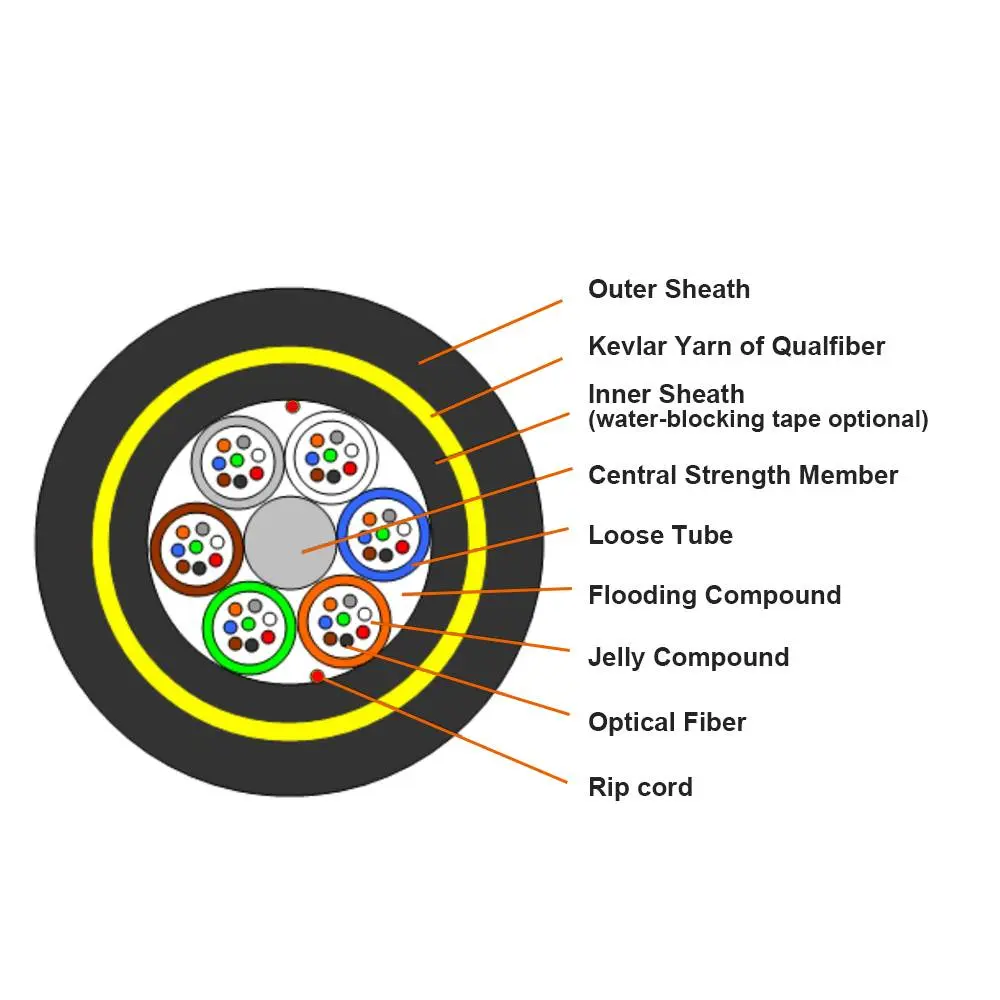

ADSS cable is aerial use Self-Supporting optical fiber cable with loose tubes stranded inside. Fibers, are positioned into a loose tube made of high modulus plastics.

The tubes are filled with a water-resistant Jelly. The tubes ( and fillers ) are stranded around a FRP ( Fiber Reinforced Plastic) as a non – metallic central strength member into a compact and circular cable core. After the cable core is filled with filling compound. it is covered with thin PE ( polyethylene ) inner sheath.

After stranded layer of aramid yarns are applied over the inner sheath as strength member, the cable is completed with PE or AT (anti-tracking) outer sheath.

Standards

Comply with IEEE 1222, IEC 60794-4-20, ANSI/ICEA S-87-640, TELCORDIA GR-20, IEC 60793-1-22, IEC 60794-1-2, IEC 60794

Suitable Installation Type

- Duct

- Aerial

- Direct Buried

Application

• High voltage power lines

• Telephone poles

• Railway overhead lines

• Utilility networks

• Rural long distance data transmission

4 Reasons to Choose Oriental Fiber

Quality Material

Advanced Technology

High Test Standard

Always Fast Response

Structure

- UV stabilised polyethelene jacket suitable for long life in a wide range of installations

- Water swellable yarns provide protection again water ingress (dry core construction)

- Non-metallic construction

- Fibreglass reinforced polymer central strength member and aramid yarn peripheral strength member provide excellent strength

- Flexible buffer tubes provide easy handle within termination enclosures

- Single layer SZ stranding limits stress on fibre tubes

- Fibre friendly thixotropic gel in tubes ensures fibre protection

- TIA 598 standard colour code

- 6 or 12 fibre tube constructions available (conditions may apply)

- 6 to 288 fibres

Oriental Fiber Manufacturer

Make Fiber Cable Procurement Easy and Cost-effective

How to check more details about a fiber optic cable?

You can check Cable Identification of Oriental Fiber Optic Cable or contact our fiber optic cable experts to make a specific datasheet for your requirements.

Specification

| Number of fiber | 12-288 cores | |||||||

| Filling rope | 2-0 | |||||||

| Moisture Barrier | Water blocking system | |||||||

| Central strength member | material | FRP/FRP with PE | ||||||

| size | 2.1mm | |||||||

| Tube-filling | Tube filling compound | |||||||

| filler | PP tube/ PVC tube | |||||||

| Inner sheath | material | PE | ||||||

| Loose tube | material | PBT | ||||||

| diameter | Ф2.2(outer/inner) | |||||||

| Outer armored | material | Aluminum tape/Corrugated steel tape | ||||||

| Outer sheath | material | PE/HDPE | ||||||

| diameter | 1.7±0.2mm | |||||||

Fiber Characteristic

| Fiber Type | OS1 | OM1 | OM2 | OM3 | OM4 | |

|---|---|---|---|---|---|---|

| 9/125μm | 62.5/125μm | 50/125μm | 50/125μm | 50/125μm | ||

| Attenuation Coefficient (+20°C) | @850nm | / | ≤3.0 dB/km | ≤3.0 dB/km | ≤3.0 dB/km | ≤3.0 dB/km |

| @1300nm | / | ≤1.5 dB/km | ≤1.5 dB/km | ≤1.5 dB/km | ≤1.5 dB/km | |

| @1310nm | ≤0.36 dB/km | / | / | / | / | |

| @1500nm | ≤0.22 dB/km | / | / | / | / | |

| OFL Bandwidth | @850nm | / | ≥200 MHz · km | ≥500 MHz · km | ≥1500 MHz · km | ≥3500 MHz · km |

| @1300nm | / | ≥500 MHz · km | ≥500 MHz · km | ≥500 MHz · km | ≥500 MHz · km | |

| Numerical Value | / | 0.275±0.015 NA | 0.200±0.015 NA | 0.200±0.015 NA | 0.200±0.015 NA | |

| Cable Cut-off Wavelength | ≤1260 nm | / | / | / | / | |

Structure Dimensions

| Item | Contents | Value G652.D | |||

| Fibers | No. of Fibers | 12 | 24 | 48 | 96 |

| Structure | Type | 1+5 | 1+5 | 1+5 | 1+8 |

| Loose tube | Number x Fibers per tube | 2×6 | 4×6 | 4×12 | 8×12 |

| No. of Tubes (+Fillers) | 5 | 5 | 5 | 8 | |

| Filling compound | Thyrotrophic jelly compound | ||||

| Material | PBT (Polybutylene terephthalate) (natural or white color) | ||||

| Diameter (nominal)/mm | 2.00 | 2.00 | 2.30 | 2.30 | |

| Thickness (nominal)/mm | 0.30 | 0.30 | 0.35 | 0.35 | |

| Central Strength Member | FRP, Diameter (nominal)/mm | 1.6 | 1.6 | 1.8 | 3.0 |

| PE layer diameter (mm) | – | – | – | 4.2 | |

| Water blocking elements | Material (cable core covering/filling) | Water swellable yarn and Water blocking Tape | |||

| Additional Strength member | Material | Aramid yarn | |||

| Ripcords | Material | Polyester cords or Plastic thread. Color red | |||

| Number | One | ||||

| Inner Sheath (Jacket) | Material | Black PE (Polythene) | |||

| Thickness (nominal)/mm | Nominal: 0.8 mm | ||||

| Outer Sheath (Jacket) | Material | UV-Proof High density black polyethylene (HDPE) | |||

| Thickness (nominal)/mm | 1.7 | 1.7 | 1.7 | 1.7 | |

| Cable diameter (nominal)/mm | 9.8 | 10.2 | 11.0 | 13.4 | |

| Allowable Maximum Span (m) | 200M | ||||

| Cable weight | Kg/km (nominal) | 94 ~ 101 | 94 ~ 101 | 119 ~ 127 | 128~135 |

| Packing | Wooden reel, 2.0km/reel±0.5% | 940*700 | 940*700 | 1040*600 | 1040*600 |

| Item | Specifications | |

|---|---|---|

| Optical Cable Core | 1 Tube * 12 Core | |

| Fiber Color | Blue, Orange, Green, Brown, Gray, White, Red, Black, Yellow, Purple, Pink, Aqua | |

| Loose Tube | Diameter | 2.0 ± 0.1mm |

| Color | White | |

| Strength Member | FRP | 2.0 ± 0.1mm * 2 |

| Outer Jacket | MDPE (UV) | 1.7 ± 0.1mm |

| Color | Black | |

| Permit Span | M | 80 M |

| Permit Wind Speed | KM/h | 20 KM/h |

| Permit Thickness of Ice | MM | 0 mm |

| Cable Nominal Diameter | MM | 8.0 ± 0.3 |

| Cable Weight | Kg/KM | 70 ± 5% |

| Bending Radius | Static | 10 D |

| Dynamic | 20 D | |

| Flattening Force | Long term | 200N/100mm |

| Short term | 500N/100mm | |

FAQs

What is ADSS Fiber Cable?

All-Dielectric self supporting cable and single jacket designed for aerial installation. The optical fiber cable(ADSS) design provides no supporting part or messenger wire required.

Oriental Fiber provides for hardware part for installation with ADSS cable supporting on the pole. The cable inside multi-loose tube filled with a water resistant filling compound or design for waterblocked with water blocking material in side cable. The cable high tensile by aramid yarns and FRP strength member rod inside. Outer sheath made from HDPE.

What is Technical Characteristics of ADSS Fiber Cable?

Due to the process innovation and technical breakthrough made on the basis of the conventional Single-mode fibre, FullBand ® low water peak Single-mode fibre has the following characteristics:

- Designed for operation over the full optical spectrum from 1260-1625 nm, which provides 50% more usable wavelengths and hence the transmission capacity is increased

- Outstanding optical performance supporting high-speed transmission technologies such as DWDM and CWDM

- Being compatible with existing 1310 nm equipment

- Good protection and excellent strip force stability

- Accurate geometrical parameters that insure low splicing loss and high splicing efficiency

Quick Contact Form

You will often get our response in 6 hours or less.

Factory Location:

Building A, No.110, Ninghang North Road, Jurong City, Jiangsu, China.

Email:

[email protected]

[email protected]

[email protected]

24/7 Whatsapp:

+86 186 8227 0997

+86 131 8904 9416

+86 138 1700 4898