Oriental Fiber Manufacturer

Make Fiber Cable Procurement Easy and Cost-effective

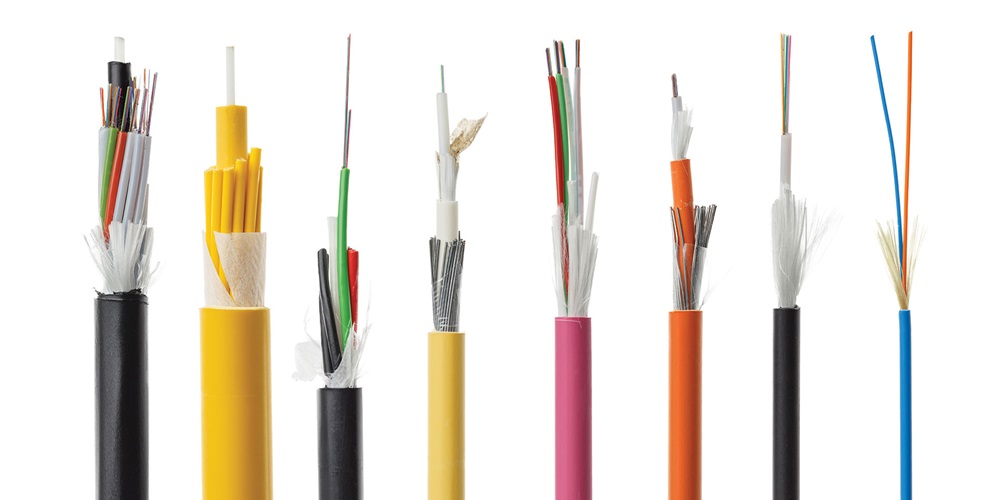

FAQ on Cable Identification of Fiber Optic Cable

Fiber color code

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

| Color | Blue | Orange | Green | Brown | Gray | White |

| No. | 7 | 8 | 9 | 10 | 11 | 12 |

| Color | Red | Black | Yellow | Violet | Pink | Aqua |

Loose tube (LT) & filler rod (FR) color code

| Fibercount | Element no. | |||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| 4 | LT | FR | FR | FR | FR | |||||||

| 6 | LT | FR | FR | FR | FR | |||||||

| 8 | LT | LT | FR | FR | FR | |||||||

| 12 | LT | LT | FR | FR | FR | |||||||

| 24 | LT | LT | LT | LT | FR | |||||||

| 48 | LT | LT | LT | LT | FR | |||||||

| 72 | LT | LT | LT | LT | LT | LT | ||||||

| 96 | LT | LT | LT | LT | LT | LT | LT | LT | ||||

| 144 | LT | LT | LT | LT | LT | LT | LT | LT | LT | LT | LT | LT |

- * “LT” means “Loose Tube”;

- ** “FR” means “Filler Rod”.

Cable Assembly & Dimensions

| Item | Contents | Value | ||||

| 4/6/8/12/24 | 48 | 72 | 96 | 144 | ||

| Loose tube | Number | 1/1/2/2/4 | 4 | 6 | 8 | 12 |

| Outer diameter (mm) | 1.8 | 2.0 | 2.0 | 2.0 | 2.0 | |

| Thickness(mm) | 0.3 | |||||

| Material | PBT | |||||

| Water blocking | Tube filling compound | |||||

| Filler | Material | PP | ||||

| Number | 4/4/3/3/1 | 1 | 0 | 0 | 0 | |

| Max. Fiber counts per tube | G.652D | 6 | 12 | 12 | 12 | 12 |

| Central strength member | Material | Steel wire | ||||

| Diameter (mm) | 1.4 | 1.55 | 2.1 | 2.0 | 2.0 | |

| PE layer diameter (mm) | — | – | – | 3.5 | 6.1 | |

| Water blocking | Material | Water blocking jelly | ||||

| Sheath | Material | HDPE | ||||

| Color | Black | |||||

| Thickness (mm) | 1.6 | |||||

| Cable diameter(mm) Approx | 9.0 | 9.6 | 10.1 | 11.5 | 14.1 | |

| Cable weight(kg/km) Approx. | 80 | 90 | 110 | 135 | 185 | |

Performance of Cabled Optical Fiber

The performance of cabled optical fiber (ITU-T Rec. G.652D)

| Item | Specification |

| Fiber type | Single mode |

| Fiber material | Doped silica |

| Attenuation coefficient@ 1310 nm@ 1550 nm | £ 0.36 dB/km£ 0.22 dB/km |

| Cable cut-off wavelength | £ 1260 nm |

| Zero-dispersion wavelength | 1300 ~ 1324 nm |

| Zero-dispersion slope | £ 0.092 ps/(nm2.km) |

| Chromatic dispersion@ 1288 ~ 1339 nm@ 1271 ~ 1360 nm@ 1550 nm@ 1625 nm | £3.5 ps/(nm. km)£5.3 ps/(nm. km)£18 ps/(nm. km)£22 ps/(nm. km) |

| PMD | £0.2 ps/km1/2 |

| Mode field diameter @ 1310 nm | 9.2±0.4 um |

| Core / Clad concentricity error | £ 0.6 um |

| Cladding diameter | 125.0 ± 0.7 um |

| Cladding non-circularity | £1% |

| Primary coating diameter | 245 ± 5 um |

Performance of Optical Fiber Cable

Cable bending radius:

- 10 x cable diameter (static)

- 20 x cable diameter (dynamic)

Application temperature range

| Operating temperature range | : -40oC to +70oC |

| Storage / Transport temperature range | : -40oC to +70oC |

| Installation temperature range | : -20oC to +60oC |

Mechanical & environmental performance test

| S/N | Item | Test Method | Acceptance Condition |

| 1 | Tensile StrengthIEC 794-1-E1 | – Load: 1.5KN- Length of cable under load: 50 m- load time: ≥1min. | – Loss change £ 0.1 dB/km@1550 nm -No damage to outer jacket and inner elements. |

| 2 | Crush TestIEC 794-1-E3 | – Load:1.0KN/100mm*100mm- Load time: ≥1min. | – Loss change £ 0.1 dB/km@1550 nm -No damage to outer jacket and inner elements. |

| 3 | Impact ResistanceIEC 794-1-E4 | – Points of impact: 5-Times of per point: 1- Impact energy:4.5N.m- Radius of hammer head: 12.5mm- Impact rate: 2 sec/cycle | – Loss change £ 0.1 dB/km@1550 nm -No damage to outer jacket and inner elements. |

| 4 | Repeated BendingIEC 794-1-E6 | – Bending radius: 20 x cable diameter- Load: 150 N- Flexing rate: 3 sec/cycle- No. of cycle: 30 | – Loss change £ 0.1 dB/km@1550 nm -No damage to outer jacket and inner elements. |

| 5 | TorsionIEC 794-1-E7 | – Length: 1 m- Load: 150 N- Twist rate: 1 min/cycle- Twist angle: ±180°- No. of cycle: 10 | – Loss change £ 0.1 dB/km@1550 nm -No damage to outer jacket and inner elements. |

| 6 | Water Penetration TestIEC 794-1-F5B | – Height of water: 1 m- Sample length: 3 m- Test time: 24 hours | – No water shall have leaked from the opposite end of cable. |

| 7 | Temperature Cycling TestIEC 794-1-F1 | – Temperature step:+20oC→-40oC→+70C →+20oC- Time per each step: 24 hours- Number of cycle: 2 | – Loss change £ 0.1 dB/km@1550 nm- No fiber break and no sheath damage. |

| 8 | Compound FlowIEC 794-1-E14 | – Sample length: 30 cm- Temp: 70°C ± 2°C- Time: 24 hours | – No compound flow |

Packaging

- Each single cable length been wound on an iron stand-wooden composite or pure wooden drum.

- Standard drum length is 4000m with ±2%.

- Covered by plastic buffer sheet.

- Sealed by strong wooden battens.

- At least 3m of cable inner end should be reserved for testing.